The Future of Makeup Brush Filaments: Customization, Precision, and Innovation

As makeup artistry continues to evolve, so do the tools used to create it. Central to the toolkit of makeup professionals and enthusiasts alike are makeup brushes, where quality and design directly impact application precision and the final look. The filament fibers in brushes, especially as synthetic materials continue to gain traction, play a critical role in achieving these high standards. Today, manufacturers are pushing the boundaries of filament technology, focusing on customization, precision, and innovation to deliver brushes that not only mimic natural hair but also exceed its performance. This article delves into how advancements in synthetic filaments are shaping the future of makeup brushes and enhancing user experience.

1. Customization: Tailoring Filament Properties to User Needs

Customization in filament production allows for creating brushes tailored to specific uses, enhancing makeup application in ways that cater to diverse skin types, makeup products, and artistic techniques.

a. Fiber Shape and Texture

Fiber shape is key to creating brushes with different textures. Round, oval, flat, and angular cross-sections can all be engineered to suit specific makeup functions. For instance, fibers with a flat cross-section work well with liquid products as they have a larger surface area for smooth application. Meanwhile, a round cross-section helps distribute powder products evenly, providing a soft, natural finish. With ongoing research into the impact of fiber shapes, manufacturers can design filaments that deliver the precise level of application coverage and finish that each type of makeup demands.

b. Custom Length and Diameter

Customization also extends to the length and diameter of filaments. Shorter, thicker fibers offer denser coverage and are often used in foundation or buffing brushes, while longer, thinner fibers are ideal for blending and diffusing. This variation in size also contributes to different levels of flexibility, allowing some brushes to be more pliable for blending, while others retain stiffness for precise application.

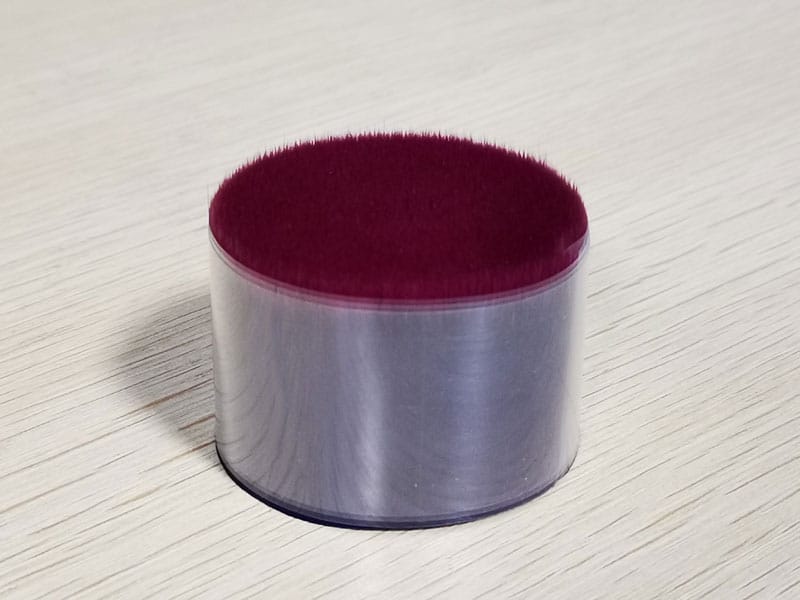

c. Custom Dyeing and Anti-Bacterial Properties

Manufacturers are also experimenting with custom dyeing and adding anti-bacterial agents to synthetic filaments. This not only enhances the aesthetic appeal of makeup brushes (such as color-coded brushes for different applications) but also improves hygiene, a factor especially valued by professionals and consumers alike.

2. Precision: Designing Filaments for Enhanced Makeup Application

Precision in makeup application is achieved through advancements in filament structure and surface treatment, ensuring that each brush delivers flawless results.

a. Controlled Tapering and Conical Tips

Through precision tapering techniques, such as physical grinding or chemical treatments, manufacturers can create conical fiber tips that enhance control and blending abilities. This approach is essential for brushes used around delicate areas, like the eyes, where precision is paramount. The gradual taper allows for softer, more seamless blending that’s often required for intricate looks, especially when working with powders or layering products.

b. Static Reduction for Improved Powder Pickup

One ongoing challenge in filament design is minimizing static cling in synthetic fibers. High static can interfere with powder pickup, causing uneven application. Manufacturers are now adding anti-static additives to synthetic filaments to counter this issue, allowing for better adherence to powder particles and smoother application. Anti-static technology also helps ensure uniform pigment distribution, creating a more even and professional result.

c. Textured Filaments for Better Product Retention

To enhance the retention of liquid and cream products, new filaments are being created with microscopic surface textures. These textures improve grip on thicker products, ensuring they stay in the brush rather than slipping off, as can sometimes happen with synthetic materials. This innovation provides a level of performance similar to natural bristles, making synthetic brushes more competitive for professional-grade makeup applications.

3. Innovation: Pioneering New Filament Technologies

Innovation in filament production is leading to synthetic makeup brushes that not only perform as well as natural hair but, in many cases, outperform traditional materials.

a. Advanced Material Blends for Enhanced Flexibility

By blending materials like PBT (Polybutylene Terephthalate) and other polyester variants with innovative additives, manufacturers can now adjust the softness, flexibility, and resilience of brush filaments. These blends allow synthetic brushes to closely mimic the feel of natural hair while offering superior durability. For example, blending PBT with biodegradable polymers creates brushes that are not only high-performing but also eco-friendly, appealing to environmentally-conscious consumers.

b. 3D Printing Technology for Unique Fiber Shapes

Some companies are exploring the use of 3D printing to create uniquely shaped filaments with complex textures that traditional manufacturing techniques cannot achieve. These custom-designed filaments provide entirely new functionalities in brushes, offering distinct grip levels for powders, creams, and liquids. With 3D printing, the industry can push the boundaries of what is possible in brush design, creating a future where custom filaments can be produced on demand.

c. Sustainable Alternatives and Biodegradable Fibers

Sustainability is driving innovation in all beauty sectors, and makeup brushes are no exception. By incorporating biodegradable additives or exploring alternative polymers, manufacturers are developing filaments that degrade more easily without compromising on performance. This movement toward sustainable synthetic fibers is aligning with growing consumer demand for eco-friendly products, positioning synthetic filaments as a responsible choice for both professionals and consumers.

4. Meeting the Demands of the Modern Consumer

The modern beauty consumer is more informed and has higher expectations than ever before. As such, manufacturers are focusing on:

a. Durability and Longevity

Consumers want brushes that last longer and maintain their structure despite repeated use and cleaning. High-quality synthetic filaments, particularly those made with durable materials like PBT, provide this longevity, offering brushes that remain effective over time without shedding or fraying.

b. Ethical and Cruelty-Free Appeal

The shift toward synthetic, cruelty-free materials has boosted the popularity of synthetic brush filaments. As the preference for cruelty-free and vegan beauty products grows, synthetic brushes offer a guilt-free alternative that performs on par with natural hair.

c. Professional-Level Performance

The availability of professional-grade synthetic filaments is changing the landscape for both consumers and makeup artists. With precision-cut shapes, anti-static treatments, and innovative materials, today’s synthetic brushes offer application results that meet the high standards of professional artistry, making them accessible to a wider audience.

5. The Future Outlook for Makeup Brush Filaments

With customization, precision, and innovation at the forefront, the future of makeup brush filaments promises tools that cater to diverse preferences, enhance artistry, and offer sustainable choices. As new technologies like 3D printing and sustainable polymers continue to develop, synthetic brushes will evolve even further, combining the best aspects of natural hair with unique synthetic benefits. These advancements allow for a level of customization previously impossible, paving the way for brushes that meet every conceivable need in makeup application, from daily use to professional artistry.

The advancements in synthetic makeup brush filaments are opening doors to unprecedented performance and versatility. As manufacturers embrace customization, precision, and innovation, consumers can expect tools that not only enhance their makeup application experience but also align with their ethical and environmental values. The future of makeup brush filaments is indeed bright, with synthetic fibers leading the way toward more tailored, high-performance, and sustainable beauty tools for all.

Leave A Comment