Anti-Static and Biodegradability – Exploring the Role of Additives in Enhancing Fiber Performance

The production of synthetic fibers for applications like eyelashes, makeup brushes, and cleaning brushes has evolved significantly in recent years. While the base materials—such as PBT, PET, and Nylon—are crucial for determining the fiber’s core properties, additives play an equally important role in enhancing the performance of these fibers. Two of the most impactful additive categories are those that impart anti-static properties and those that promote biodegradability.

This article delves into how these additives are incorporated into synthetic fibers and how they affect the final product’s functionality, durability, and environmental impact.

1. The Importance of Additives in Fiber Production

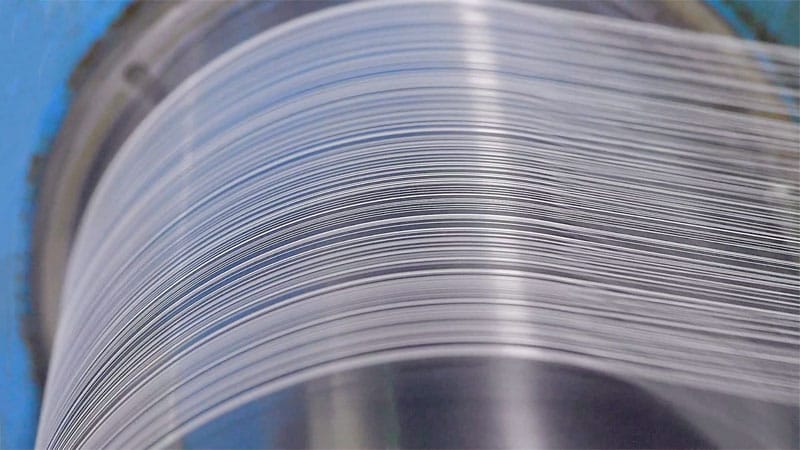

In synthetic fiber production, base materials like PBT (Polybutylene Terephthalate) and PET (Polyethylene Terephthalate) are popular choices for their durability, resilience, and smooth texture. However, these fibers sometimes require additional performance enhancements to meet the specific needs of various industries, such as cosmetics or household cleaning tools.

Additives serve this purpose by modifying or enhancing the fiber’s inherent properties. Whether improving anti-static performance to reduce flyaway fibers or incorporating additives that ensure biodegradability to meet environmental standards, these small components make a significant difference in the performance and appeal of the final product.

2. Anti-Static Additives: Smoother Application, Less Friction

One of the key challenges in synthetic fiber products—particularly in beauty and cosmetic applications—is static buildup. As synthetic materials often generate static electricity when rubbed against surfaces, this can result in flyaway fibers, poor product adhesion, and reduced overall performance in makeup brushes, false eyelashes, and cleaning tools.

Anti-static additives help address these issues by:

- Reducing static buildup: Anti-static additives reduce the amount of static charge that builds up in synthetic fibers during use. This is particularly important in makeup brushes, where static electricity can cause the bristles to repel fine powders or cause uneven product application.

- Improving usability: Anti-static fibers are more manageable for users, leading to a smoother and more consistent application, whether it’s makeup or cleaning materials. For instance, eyelash fibers treated with anti-static agents sit more naturally against the skin without sticking together or standing upright unnaturally due to charge accumulation.

- Enhancing durability: Reducing static also prevents fibers from wearing out or becoming damaged due to excessive friction during application.

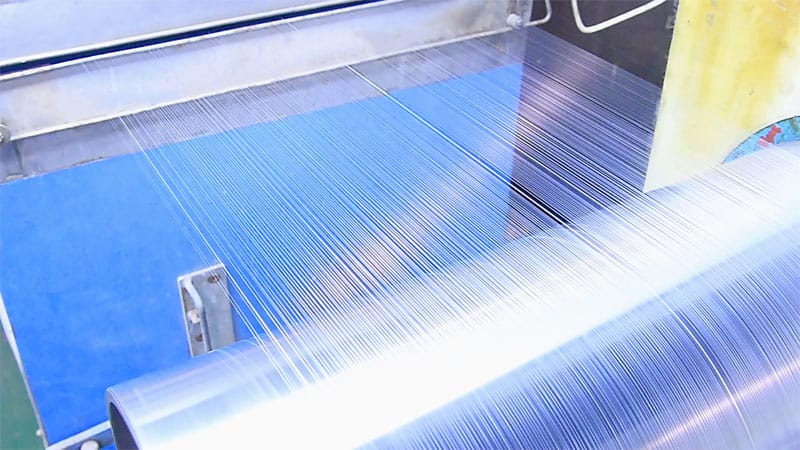

How it works: Anti-static additives are typically mixed into the polymer before the fiber is extruded, ensuring that the fiber exhibits reduced static behavior from the inside out. This makes the effect long-lasting and not just surface-level.

3. Biodegradability Additives: Meeting Environmental Demands

As environmental concerns rise, biodegradable fibers are increasingly sought after in the beauty and personal care industries. Traditional synthetic materials, such as PBT and PET, are durable but take a long time to break down in the environment. However, with the incorporation of specific biodegradable additives, these materials can decompose much faster, helping reduce their environmental footprint.

Biodegradable additives promote degradation by:

- Accelerating breakdown: Additives like anaerobic catalysts allow synthetic fibers to break down faster in specific environments, particularly in landfills, where oxygen is limited. In the case of PBT, anaerobic biodegradability can be achieved through the incorporation of catalysts that trigger decomposition under the right conditions.

- Maintaining performance: Despite being designed to break down more easily, biodegradable fibers retain their strength, flexibility, and performance during use. For instance, biodegradable false eyelashes perform just as well as traditional ones in terms of application, comfort, and durability, but degrade more quickly after disposal.

PBT with anaerobic catalysts is one example of how biodegradability can be introduced to synthetic fibers without sacrificing their performance. These catalysts work specifically in low-oxygen environments, ensuring that the material remains stable during regular use but breaks down efficiently once discarded in landfills.

4. Experimental Data on Biodegradability

Biodegradability isn’t just a marketing buzzword—it can be scientifically measured and proven. Laboratory experiments conducted on biodegradable PBT fibers have shown:

- Faster decomposition rates: Compared to standard PBT fibers, which can take decades or even centuries to break down, biodegradable PBT fibers degrade within a much shorter timeframe. In specific test environments mimicking landfill conditions, these fibers showed significant decomposition within two to three years, compared to the negligible degradation seen in conventional PBT over the same period.

- Environmental impact assessments: Studies have also indicated that these fibers break down into non-toxic, inert materials, which do not harm soil or water ecosystems during decomposition. This makes them a responsible choice for industries concerned with reducing their ecological footprint.

These results demonstrate that biodegradability is a feasible and practical solution for reducing waste from disposable beauty products like false eyelashes or makeup brushes.

5. The Perfect Balance: Combining Anti-Static and Biodegradability

Interestingly, modern fiber production techniques allow manufacturers to incorporate multiple additives into a single fiber to deliver a balance of benefits. For example, PBT fibers used in disposable false eyelashes can be enhanced with both anti-static properties for improved wearability and biodegradability for a reduced environmental impact.

These combined fibers are ideal for disposable beauty products, such as temporary eyelashes, which need to offer high performance during use but break down efficiently once discarded. For consumers, this means they can enjoy high-quality beauty products without worrying about their environmental consequences.

6. Applications in Eyelash and Makeup Brush Manufacturing

For manufacturers, the choice of whether to use anti-static, biodegradable, or a combination of both additives depends on the specific product and market demand.

- False eyelashes: Disposable eyelashes made from biodegradable PBT provide an eco-friendly alternative for consumers, especially as single-use items are a growing concern in the beauty industry. Anti-static treatments further enhance these lashes by making them easier to apply and ensuring they stay in place without clumping or attracting dust and debris.

- Makeup brushes: Brushes made with anti-static-treated fibers offer smoother application of powder, cream, or liquid products, giving makeup artists better control and precision. For disposable or eco-friendly lines, manufacturers can incorporate biodegradable fibers, maintaining both performance and sustainability.

The role of additives in synthetic fiber production goes beyond mere functional enhancements; it represents the intersection of innovation and sustainability. Whether improving anti-static properties for better usability or adding biodegradable catalysts to reduce environmental impact, these additives are critical in shaping the future of synthetic materials used in eyelashes, makeup brushes, and more.

By continually advancing additive technologies, manufacturers can meet the evolving demands of consumers—offering products that not only perform better but also align with the increasing need for eco-friendly solutions in the beauty and personal care industry.

Leave A Comment