Biodegradable Eyelash Fiber Raw Materials

With growing demand for sustainable materials, biodegradable eyelash fiber raw materials are becoming a focus in the beauty industry. These materials are not just about meeting environmental standards but also about maintaining product performance while reducing their long-term impact. This article delves into the technical aspects of biodegradable fibers, particularly PBT (polybutylene terephthalate) and its modifications, the experimental studies backing their performance, and the production advancements that are making them more viable for commercial use.

1. Origins of Biodegradable Eyelash Fibers: A Technical Perspective

Traditional eyelash fibers are typically made from synthetic materials like PBT, PET, or Nylon—polymers known for their durability and flexibility but also for their resistance to natural degradation. In response to environmental concerns, efforts have been made to modify these materials for biodegradability without compromising their physical properties, especially in applications like false eyelashes, where flexibility, softness, and wearability are crucial.

PBT and Biodegradability: PBT has been widely used in synthetic lashes due to its excellent properties: high strength, flexibility, and resistance to chemicals and heat. However, its non-biodegradability posed a challenge. Recent developments have focused on incorporating anaerobic catalysts into the PBT matrix. These catalysts activate under landfill conditions, promoting the breakdown of PBT in anaerobic (oxygen-free) environments. The inclusion of these catalysts allows PBT to degrade into simpler molecules within a controlled period, typically ranging from 5 to 10 years in landfills, compared to hundreds of years for traditional PBT.

2. Development Timeline: From Traditional Synthetics to Advanced Biodegradable Fibers

Early Innovations: The first steps toward biodegradable fibers focused on combining synthetic polymers with plant-based materials. While these early attempts were promising, the mechanical properties of the fibers were not ideal for the precision and aesthetic standards of false eyelashes.

PBT + Anaerobic Catalyst Modification: Around the mid-2010s, scientists began to explore the inclusion of anaerobic catalysts that could trigger the degradation process in synthetic polymers like PBT. Unlike purely natural materials, this innovation allowed for the continued use of high-performance synthetic polymers in eyelashes while making them more environmentally friendly. The catalysts initiate a chemical reaction under landfill conditions, breaking down the polymer chains into smaller molecules that can then be consumed by microorganisms.

Recent Advancements: By the 2020s, biodegradable PBT fibers became more sophisticated. Manufacturers refined the polymer blends, enhancing their mechanical performance while ensuring controlled degradation under specific conditions. Advanced testing and validation of these materials demonstrated their viability for commercial applications.

3. Characteristics of Biodegradable Eyelash Fibers

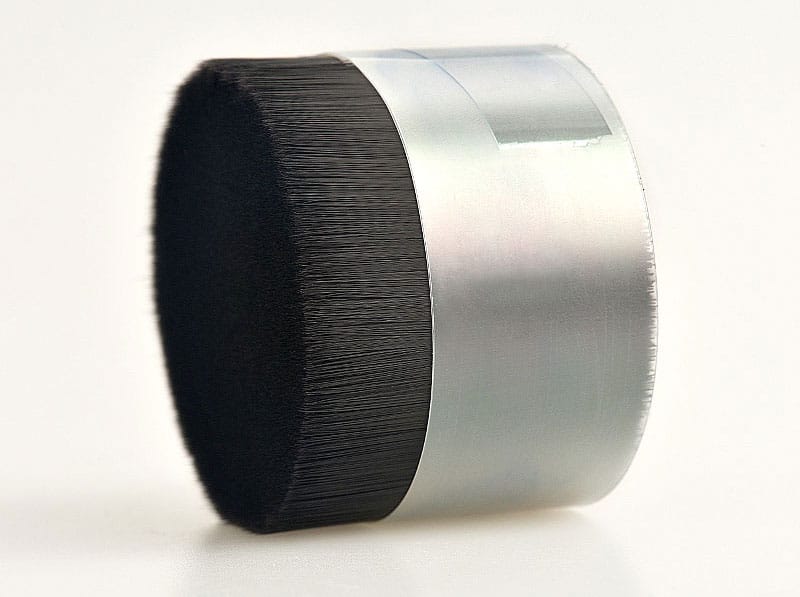

Biodegradable fibers, especially those derived from modified PBT, maintain many of the beneficial properties of their non-degradable counterparts, while offering the added benefit of environmental sustainability. These fibers are particularly valuable for their performance in false eyelash production, where softness, durability, and a natural aesthetic are essential.

- Biodegradability with Performance: By incorporating anaerobic catalysts into PBT, manufacturers have achieved fibers that degrade under anaerobic conditions (e.g., in landfills) while retaining their strength, flexibility, and appearance during use.

- Controlled Degradation Time: Laboratory tests have shown that modified PBT fibers can biodegrade in 5 to 10 years under typical landfill conditions, as opposed to hundreds of years for conventional PBT. This is achieved without sacrificing the physical properties required for high-quality eyelashes.

- Softness and Flexibility: Biodegradable fibers retain the softness and flexibility of traditional synthetic lashes, ensuring they remain comfortable and aesthetically pleasing for wearers.

4. Experimental Data Supporting Biodegradable PBT Fibers

Several studies have been conducted to validate the effectiveness of biodegradable PBT fibers in controlled environments. The tests typically simulate landfill conditions, measuring the rate of polymer breakdown over time.

Anaerobic Degradation Testing: In a controlled laboratory environment mimicking landfill conditions, biodegradable PBT with anaerobic catalysts showed a degradation rate of approximately 30% mass loss within 2 years. This degradation rate increased significantly under more extreme conditions (e.g., higher temperatures or enhanced microbial activity), with up to 70% mass loss in 5 years.

Tensile Strength and Durability: Despite their biodegradability, these fibers exhibited strong mechanical properties during their functional lifetime. Tensile strength testing indicated that biodegradable PBT fibers retained 95% of their tensile strength after 50 cycles of mechanical stress testing, equivalent to the performance of non-degradable PBT lashes.

Environmental Impact: A lifecycle assessment study demonstrated that the carbon footprint of biodegradable PBT fibers was reduced by up to 40% compared to conventional synthetic fibers due to faster breakdown in landfills and reduced long-term environmental impact.

5. Advantages of Biodegradable Eyelash Fibers

Unlike traditional discussions focusing solely on the environmental benefits of biodegradability, the real strength of biodegradable fibers lies in their ability to maintain performance while offering sustainability benefits. The key advantages include:

1. Comparable Performance: Despite the added feature of biodegradability, the functional properties of these fibers are comparable to those of traditional synthetic fibers. This is essential for maintaining product quality, especially in beauty products like false eyelashes, where precision and aesthetics matter.

2. Shorter Environmental Impact Timeline: The biodegradable fibers, especially those made from PBT with anaerobic catalysts, break down much faster than conventional materials. Instead of lasting for centuries in landfills, these materials decompose within a few years, significantly reducing their environmental footprint.

3. Customization and Versatility: Biodegradable fibers can be tailored for different cross-sectional profiles using advanced molds, meeting the varying demands of eyelash production. For instance, fibers with circular, flat, or triangular cross-sections are developed to offer different levels of volume and curl retention, ensuring that manufacturers can maintain a wide range of product offerings.

4. Minimal Compromise on Durability: While biodegradable fibers are designed to break down in specific conditions, their in-use durability remains intact. These fibers can be subjected to high-temperature dyeing processes, repeated wear, and other mechanical stresses without losing their structural integrity prematurely.

6. Application of Biodegradable Fibers in Eyelash Manufacturing

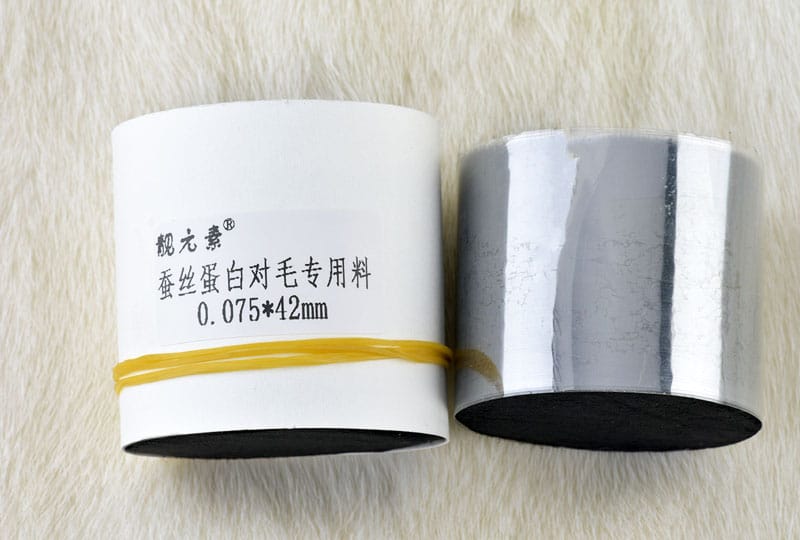

Biodegradable PBT fibers have now become a practical alternative in the eyelash manufacturing process. After being drawn from the extrusion machine, the fibers are initially cut into lengths of approximately 1.2 meters to form fiber spools. These spools are then further processed based on specific requirements:

- Cutting and Shaping: Depending on the final product, the fibers are cut into the desired lengths and shaped. For certain lash types, physical grinding is applied to taper the fiber tips for a more natural appearance. Alternatively, chemical oxidation methods can be used to achieve the same tapering effect.

- Dyeing and Finishing: High-temperature dyeing is used to achieve the desired color, and the fibers are organized by machine and manually finished to ensure precision.

- Packaging and Sustainability: As more brands embrace biodegradable fibers, the use of sustainable packaging materials has also gained attention, reducing the overall environmental impact of the product.

7. Conclusion

The development of biodegradable eyelash fibers, particularly those using modified PBT with anaerobic catalysts, represents a significant technical achievement in the beauty industry. These fibers offer both the performance required for high-quality eyelash products and the environmental sustainability increasingly demanded by consumers. With their controlled biodegradability, strong performance characteristics, and versatile applications, biodegradable fibers are poised to play a major role in the future of eyelash manufacturing.

Leave A Comment