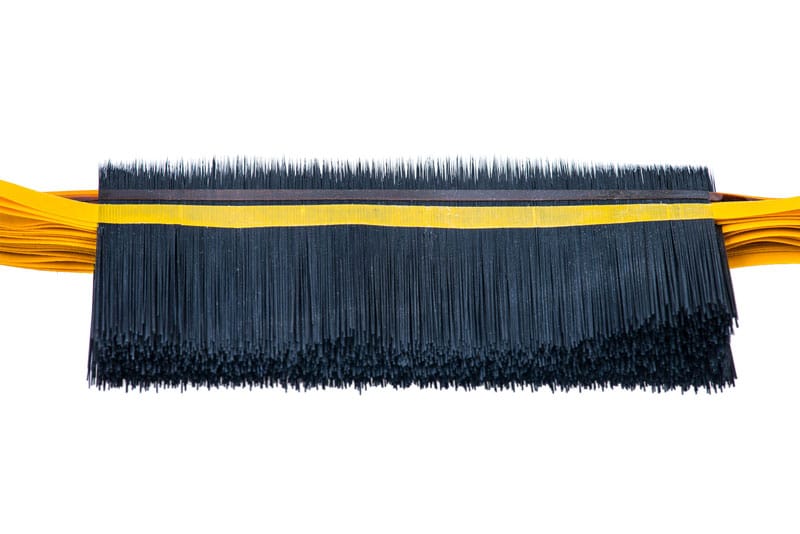

Raw Material For Eyelash Extensions, Why PBT Raw Material Remains a Top Choice for Synthetic Eyelashes and Makeup Brushes

In the world of beauty manufacturing, materials matter. For synthetic eyelashes and makeup brushes, Polybutylene Terephthalate (PBT) has long stood out as a top choice. Known for its durability, versatility, and unique performance characteristics, PBT continues to dominate the industry for good reasons. This article explores why PBT remains the go-to material for creating high-quality synthetic fibers in both eyelashes and makeup brushes.

1. Durability and Flexibility

One of the key reasons PBT is widely used in synthetic eyelashes and makeup brushes is its incredible durability. The fibers made from PBT can withstand repeated use without losing their shape or breaking down. This is particularly important in the beauty industry, where products like makeup brushes are expected to last through countless applications and cleanings. PBT is highly resistant to wear and tear, making it ideal for long-term use in professional settings as well as everyday use by consumers.

At the same time, PBT fibers offer flexibility. In synthetic eyelashes, this flexibility ensures a natural look and feel, closely mimicking the bend and flow of natural lashes. For makeup brushes, it ensures the bristles have enough give to blend products seamlessly, while still maintaining their shape.

2. Heat Resistance and Shape Retention

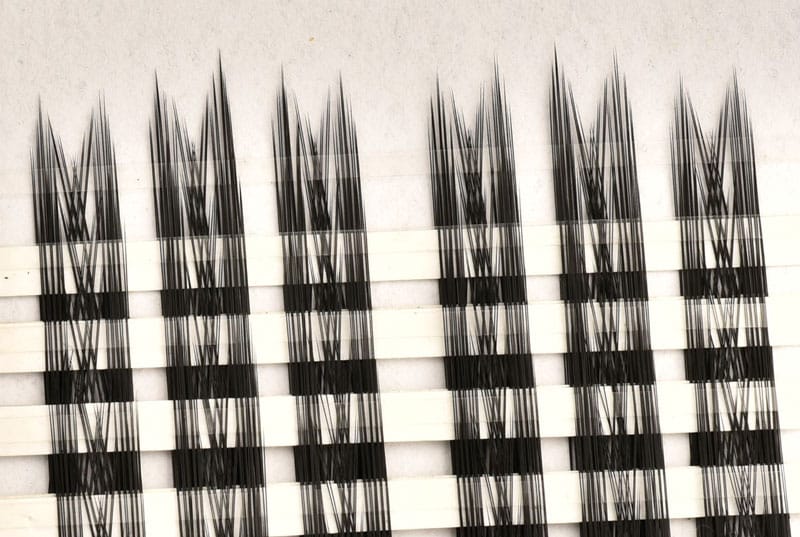

PBT fibers are known for their heat resistance. Whether they are being curled in synthetic lashes or shaped for specific brush designs, PBT fibers can endure high temperatures without melting or becoming deformed. This property is particularly valuable in the eyelash industry, where synthetic lashes often go through heating processes to achieve various styles and curls. The ability to retain a pre-set shape even after multiple uses gives PBT an advantage over other synthetic fibers that may lose their form over time.

For makeup brushes, heat resistance is crucial during the sterilization process and when brushes are exposed to the heat of makeup products like cream-based formulas. PBT fibers retain their original structure, ensuring consistent performance.

3. Softness and Texture

While durability is essential, comfort is equally important, especially in products that come into contact with sensitive areas such as the eyes and skin. PBT fibers are naturally soft, which makes them a great material for both eyelashes and makeup brushes. The smooth, non-abrasive texture of PBT ensures that false eyelashes sit comfortably on the eyelids, providing a natural feel throughout the day. Similarly, the soft bristles in makeup brushes glide smoothly over the skin, offering a pleasant experience while applying makeup.

PBT’s softness does not come at the expense of strength, making it a rare material that combines both comfort and durability.

4. Versatility in Design

One of PBT’s most significant advantages is its versatility in manufacturing. The fiber can be customized to suit a wide range of needs, from ultra-fine eyelash extensions to denser fibers for makeup brushes. PBT can be tapered, dyed, and shaped using a variety of methods, allowing manufacturers to offer different textures and styles.

For synthetic eyelashes, PBT fibers can be tailored to create everything from natural-looking lashes to bold, dramatic styles. They can be made in different thicknesses, lengths, and curls to accommodate various consumer preferences. PBT’s ability to hold a curl means that lash manufacturers can produce high-quality, long-lasting products that maintain their intended shape.

In makeup brushes, PBT’s customizability enables the production of brushes with specific functions, such as blending, contouring, or precise application. The ability to create tapered ends for detail work or fuller fibers for blending gives manufacturers the flexibility to meet market demands.

5. Eco-Friendly and Biodegradable Options

As environmental awareness grows, the beauty industry is under increasing pressure to adopt sustainable practices. While PBT is traditionally a synthetic polymer, advancements in materials science have led to the development of biodegradable PBT fibers. By adding anaerobic catalysts during production, manufacturers can produce PBT fibers that degrade more rapidly in specific environments, reducing their environmental impact.

This innovation makes PBT not only a reliable choice for performance but also an eco-conscious option. Manufacturers are increasingly choosing biodegradable PBT to meet consumer demand for more sustainable beauty products without compromising on quality.

6. Cost-Effectiveness

PBT offers a cost-effective solution for manufacturers without sacrificing quality. Its longevity, combined with its ability to be produced in large quantities, makes it an affordable option for synthetic eyelashes and makeup brush filaments. In comparison to natural fibers like mink fur or animal hair, PBT is much more economical while providing similar or superior performance characteristics.

For consumers, this cost-effectiveness translates into affordable, high-quality beauty tools and false eyelashes. PBT-based products allow for a balance between premium performance and accessible pricing, ensuring they are competitive in the mass market.

PBT fibers remain a top choice for synthetic eyelashes and makeup brushes due to their unique combination of durability, heat resistance, softness, and versatility. From holding the perfect curl in false lashes to ensuring precise makeup application with brushes, PBT continues to meet the high demands of the beauty industry. Its adaptability in design and the development of biodegradable versions further solidify its relevance in the ever-evolving market. As the industry shifts toward sustainability and innovation, PBT remains at the forefront, offering manufacturers and consumers alike a material that delivers both performance and value.

Leave A Comment